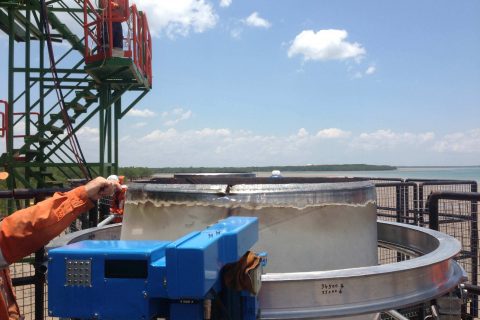

Goldmont Engineering sub-contracts on construction work. Our specialty is cutting and weld preparation of raked piles commonly used in jetty or wharf construction.

The in-house developed Automated Pile Cutter (APC) machine will cut and weld prep a raked pile in less than one hour.